UNI EN 13034

Acid-resistant Workwear

Work and protective clothing bearing the EN 13034:2009 pictogram, type 6 and PB 6, constitute the lowest level of chemical protection. Specifically, garments in this category are designed to offer protection against potential exposure to small amounts of light splashes, liquid aerosols, or accidental splashes of non-immediately dangerous chemicals.

The scope of application covers all work processes involving chemicals that could pose a hazard to workers’ health, distinguishing and including:

- Chemical agents;

- Hazardous chemical agents (agents for which, irrespective of their classification, an occupational exposure limit value has been established and which could potentially endanger workers’ health);

- Hazardous chemical preparations.

Chemical Risk: What Are We Dealing With?

When we discuss chemical risk in the workplace, we are referring to all the health and safety risks stemming from the presence of hazardous chemical agents. Article 222 of Italian Law Decree No. 81 of 2008, which references REGULATION (EC) No. 1907/2006 of 18 December 2006, defines hazardous chemical agents as follows:

“Chemical agents classified as dangerous substances as per Legislative Decree No. 52 of 3 February 1997 (…), excluding substances dangerous solely for the environment; chemical agents classified as dangerous preparations as per Legislative Decree No. 65 of 14 March 2003 (…), excluding preparations dangerous solely for the environment, and chemical agents that, even if not classifiable as dangerous, may pose a risk to workers’ safety and health due to their physicochemical or toxicological properties and their presence or usage in the workplace, including chemical agents with assigned occupational exposure limit values.”

When to Utilise Acid-Restitant Workwear

There are various work activities in which chemical risk is pertinent. In addition to industries involved in the production, synthesis, and distribution of chemical products, other sectors worth mentioning include:

- Clinical research laboratories and hospitals, where reagent substances and solutions used for therapies and analyses are managed and stored.

- Construction, where enamels, solvents, and other products with high degrees of toxicity and volatility are employed for painting and cement or adhesive production.

- Metalworking, where metals that may contain hazardous chemicals are utilised and processed.

Generic Requirements of the Acid-Resistant Protective Workwear

General requirements for acid-retardant protective workwear:

- Waterproof, preventing the penetration and permeation of hazardous chemicals throughout the entire work shift.

- Breathable, delaying the passage of acid agents, giving the operator time to remove the garment if corrosive substances come into contact with the fabric.

Instructions for acid-resistant workwear must include all the necessary information regarding the garment’s unique features and the protection it provides against one or more substances.

Additional Information About Acid-Resistant Protective Workwear

Tests

EN ISO 6530 METHOD

Before selecting the attire, it may be helpful to understand the permeation index, which indicates the time it takes for the chemical agent to pass through the material and reach the skin.

When the chemical agent’s pass-through time exceeds 480 minutes (the maximum duration of the test), it indicates that, throughout the entire trial period, the average permeation rate did not reach the standardised value. Therefore, the chemical has not successfully penetrated. These tests are conducted on all garments bearing the UNI EN 13034:2009 certification.

Acid-resistant workwear is categorised based on the time it takes for the chemical agent to permeate the fabric, as follows:

| PROTECTION INDEX | PERMEATION TIME (MIN) | |

|---|---|---|

| Class 1 | >10 | |

| Class 2 | >30 | |

| Class 3 | >60 | |

| Class 4 | >120 | |

| Class 5 | >240 | |

| Class 6 | >480 |

The table below lists the various standards for acid-resistant clothing categorised into different categories:

| TipE | PROTECTION TYPE | standard | Category | |

|---|---|---|---|---|

| 1 | Gas-tightness | EN 943-1 EN 942-2 |

III | |

| 2 | Non-gas-tightness | EN 943-1 | III | |

| 3 | Liquid tightness (high-pressure jet) |

EN 14605 | III | |

| 4 | Liquid tightness (spray get) |

EN 14605 | III | |

| 5 | Tightness to solid particles | EN 13982-1 | III | |

| 6 | Limited splash resistance | EN 13034 | II |

METHOD UNI EN 14325:2018

This standard defines the criteria for assessing the performance and testing methods of materials employed in acid-resistant protective clothing, encompassing gloves and footwear.

The tests involve the evaluation of material resistance across various cycles, including abrasion, bending cracking, bending at -30°, tearing, tensile strength, and perforation.

| Class | Abrasion | bending | tearing |

|---|---|---|---|

| 6 | > 2000 | > 100000 | > 150 N |

| 5 | > 1500 | > 40000 | > 100 N |

| 4 | > 1000 | > 15000 | > 60 N |

| 3 | > 500 | > 5000 | > 40 N |

| 2 | > 100 | > 2500 | > 20 N |

| 1 | > 10 | > 1000 | > 10 N |

| Class | burst | Traction | Perforation |

|---|---|---|---|

| 6 | > 850 kPa | > 1000 N | > 250 N |

| 5 | > 640 kPa | > 500 N | > 150 N |

| 4 | > 320 kPa | > 250 N | > 100 N |

| 3 | > 160 kPa | > 100 N | > 50 N |

| 2 | > 80 kPa | > 60 N | > 10 N |

| 1 | > 40 kPa | > 30 N | > 5 N |

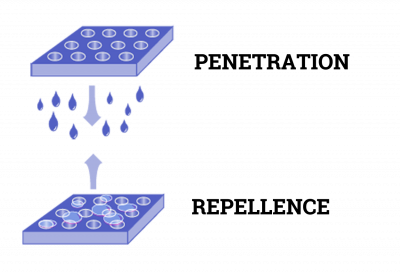

RESISTANCE TO LIQID PENETRATION – EN ISO 6530 METHOD

This method assesses the penetration and repellence indices of materials.

Penetration refers to the chemical passing through holes or openings in the material, while repellence is the material’s ability to repel liquid on its surface.

The test is straightforward: the fabric under examination is placed in a gutter lined with absorbent material, inclined at 45°. Ten millilitres of liquid are poured over the surface in ten seconds. After one minute, the amount of liquid permeated into the fabric (penetration) and that which dropped into the cup (repellence) are recorded as percentages.

The test is conducted with four defined chemical.

| Substance |

|---|

| Sulfuric Acid (H2S04) 30% |

| Sodium hydroxide (NaOH) 10% |

| O-xylene |

| Butane -1-olo |

A material is considered compliant if, for at least one chemical substance, it achieves class 3 repellency and class 2 penetration (as per EN 14325). This does not apply to PB6 partial body protective clothing (lab coats, aprons, sleeves, etc.).

| Class | Repellency | Penetration |

|---|---|---|

| 3 | > 95% | < 1% |

| 2 | > 90% | < 5% |

| 1 | > 80% | < 10% |

EN 17491-4 specifies methods for determining the resistance of chemical protective clothing to penetration by liquid chemical sprays at two different intensity levels.

Explore our completerange of Acid-resistant workwear products.