UNI EN ISO 11612

Protective Clothing Against Heat and Flame

The UNI EN ISO 11612:2015 standard delineates the performance criteria for garments fashioned from flexible materials designed to shield the wearer’s body from engulfing flames and intense radiant heat, including situations involving flames and high-risk firefighting and rescue operations. This standard excludes head, hand, and foot protection, with the exception of gaiters, hoods, and boot covers. Additional protection is recommended for these particularly vulnerable areas.

The UNI EN ISO 11612:2015 standard posits three levels of performance:

- Low perceived risk exposure.

- Medium perceived risk exposure.

- High perceived risk exposure.

These garments must offer protections of various types:

- Limited flame spread: A1) surface ignition, A2) edge ignition.

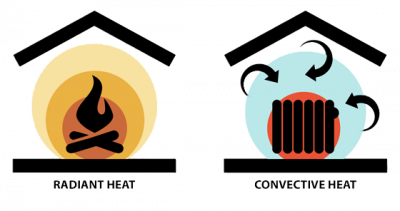

- Protection against convective heat (the heat that passes through the garment that comes into contact with the flame). The fire-resistant fabric will remain undamaged, but the body may still be at risk. B1 – B3.

- Protection against radiant heat. C1 – C3.

- Protection against molten aluminium splashes. D1 – D3.

- Protection against molten iron splashes. The test provides an indication of the fabric’s resistance to molten metal splashes. E1 – E3.

- Protection against contact heat. F1 – F3.

What does 11612 clothing protect against?

Protective clothing certified under UNI EN ISO 11612:2015 falls into Category III PPE, indicating a very high-risk standard. These garments assure protection against extreme exposure to radiant heat (C), molten aluminium splashes (D), molten iron splashes (E), and convective heat (B).

|

# | Levels of performance |

| A | Limited flame spread (A1 o A2) | |

| B | Resistance to convective heat (performance index 1-3) | |

| C | Resistance to radiant heat (performance index 1-4) | |

| D | Molten aluminum splash (performance index 1-3) | |

| E | Molten iron splash (performance index 1-3) | |

| F | Contact heat (performance index 1-3) |

Scope of Application

Heat and flame-retardant workwear is employed in the most severe scenarios by qualified personnel such as firefighters, enabling them to operate in direct contact with flames. This type of clothing is also used in occupations like foundries or metalworking industries, given its capacity to withstand temperatures up to 1000°C. The applications include:

- Maximum protection in situations with engulfing flames or those necessitating crossing flames.

- Interventions in specific fire and high-risk rescue scenarios.

Fire proximity coveralls |

Fire proximity coat, trousers |

|---|---|

|

|

| Aircraft rescue and aerial firefighting. Handling flammable liquids and gases. High radiant heat environments. |

Shipbuilding. Airport staff. Aluminium, automotive, cement, ceramic, metal, glass, iron and steel industries. Foundries and welding operations. |

General Requirements for Heat and Flame Protective Clothing:

Aluminized heat-resistant protective clothing typically comprises three layers:

- The outer surface, mirrored with an aluminized coating, reflects 95% of radiant heat up to temperatures of approximately 1093°C. Heat resistance is assured by the meta-aramid fibre, which makes up almost 95% of this layer, with the remaining 5% being para-aramid fibre, enhancing mechanical strength.

- The middle layer comprises one or more layers of soft, lightweight, flame-retardant carbon felt, capable of withstanding direct flames with peaks reaching around 800°C without substantial dimensional changes.

- The innermost layer consists of viscose, a fabric comfortable against the skin and offering heat resistance due to the presence of an aramid component.

When using aluminized heat-resistant clothing, it is imperative to wear an undergarment for added protection. Please note that leather can only be employed for this purpose in gloves.

Additional Information on the UNI EN ISO 11612 Standard:

The standard governing the characteristics of aluminized heat-resistant protective clothing is UNI EN ISO 11612:2015, which should not be confused with the UNI EN 1486:2008 standard, encompassing reflective protective clothing for firefighters.

Furthermore, several standards regulate accessory characteristics:

- UNI EN ISO 13688:2013: This standard specifies general performance requirements for ergonomics, safety, size designation, ageing, compatibility, and labelling of protective clothing. It must be used in conjunction with other norms containing specific performance requirements.

- UNI EN 420:2010: This standard defines general requirements and corresponding test procedures for glove design and manufacture, resistance to water penetration, safety, comfort, efficiency, marking, and manufacturer-provided information applicable to all protective gloves.

- UNI EN 407:2004: This standard specifies requirements, test methods, information, and marking of protective gloves against heat and/or fire, particularly fire, contact heat, convective heat, radiant heat, small splashes, or large projections of molten metal. This standard applies only in conjunction with UNI EN 420.

- UNI EN 388:2019: This standard specifies requirements, test methods, marking, and information provided by the manufacturer for protective gloves against mechanical risks like abrasion, blade cut, laceration, perforation, and, if applicable, impact. This standard also applies with UNI EN 420.

- UNI EN 166:2004: This standard specifies the functional requirements for various types of individual eye protectors and contains general considerations such as designation, classification, basic requirements applicable to all eye protectors, various details, and optional requirements, marking, and user information. This standard applies to fire proximity hoods.

- UNI EN 170:2003: This standard specifies scale numbers and transmission factor requirements for filters designed to protect against ultraviolet radiation. This standard is relevant to fire proximity hoods.

- UNI EN 397:2013: This standard specifies physical and performance requirements, test methods, and marking requirements for industrial protective helmets.

Visit the website to explore the complete range of heat and flame protective clothing products.