UNI EN ISO 20471

High-Visibility Workwear

When we encounter the pictogram corresponding to the UNI EN ISO 20471 standard, it signifies high-visibility personal protective equipment. This standard, which has replaced its predecessors, eliminates the differentiation between high-visibility safety attire for personal and professional usage. The standard also prescribes three classes with increasing levels of protection.

When using High-Visibility Safety Workwear

Numerous workplaces employ this type of attire.

Generally, these are workplaces where a portion of tasks occurs in proximity to moving vehicles, cranes, or other motorised vehicles, or under conditions of reduced visibility. Specifically, the personnel who are required to don this type of attire include:

- Workers on road construction sites;

- Airport operators;

- Construction workers;

- Surveyors;

- Engineers;

- Environmental workers.

General Characteristics and Varieties of High-Visibility Clothing

In accordance with the UNI EN ISO 20471 standard, high-visibility clothing is categorised into three classes based on the level of protection they offer and must incorporate specific minimum areas of retro-reflective, fluorescent, and/or combined materials. In detail:

- Class 1, defines the lowest visibility level, suitable only for work on private roads. Garments in this category must feature 2 metres of 5 cm wide reflective tape, 0.10 m2 of retro-reflective material, and 0.14 m2 of fluorescent background. Suspender-type attire falls into this class;

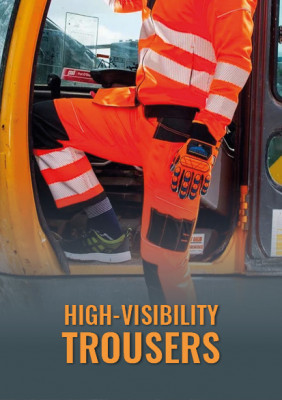

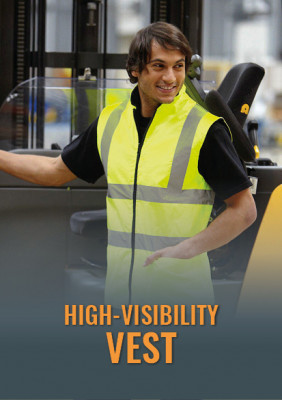

- Class 2, designates an intermediate level of visibility. This type of attire is suitable for couriers and those working near suburban (B, C), urban (D, E), and local (F) roads. Garments in this class should have a 2.60-meter reflective tape, 5 cm wide, 0.13 m2 of retro-reflective material, and 0.5 m2 of fluorescent background. Pants, vests, bibs, and hip-open tunics fall into this category.

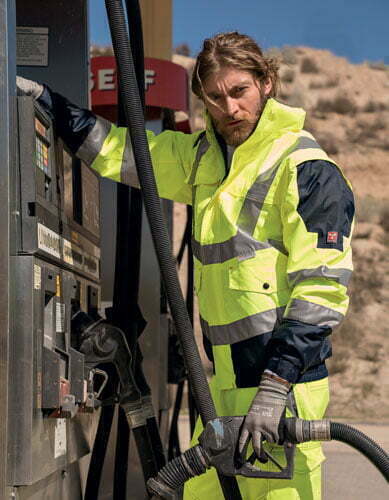

- Class 3, represents the highest level of visibility. This class encompasses all personnel working near airports, urban roads (D, E), suburban roads (B, C), or motorways (A). Attire in this category must cover the chest and include at least 4 metres of 5 cm wide reflective tape, 0.2 m2 of retro-reflective fabric, and 0.80 m2 of fluorescent background material, which should be affixed to sleeves and trousers.

Class 2 garments, when properly combined, can be considered as Class 3 attire, such as the combination of overalls and a jacket or pants and a jacket.

Technical details on the EN ISO 20471 standard

n compliance with the EN ISO 20471 standard, the manufacturer must conduct specific tests related to the retro-reflective tape and display the results on the label, indicating the maximum number of washing and drying cycles the garment can endure while preserving its high-visibility characteristics.

Visibility in Daylight Conditions

Daylight visibility is ensured by fluorescent colours. The UNI EN ISO 20471 standard recognizes three colour types: red, orange, and yellow. This material must guarantee:

- Resistance to UV exposure and moisture;

- Mechanical durability and resistance to water vapour;

- Colour Fastness.

The specified colours are evaluated through measurement with a spectrophotometer, a measurement instrument that captures the colour’s DNA: the spectral values. Colour professionals use this data to specify, communicate, and monitor colour consistency throughout the production process.

Nighttime Visibility

Glass microspheres are applied to a sturdy fabric support, such as cotton or nylon, coated on one side with a transparent, flexible resin in which more than 60 million glass microspheres, each with a 40-micron diameter, are partially embedded. Light hits the inner surface and reflects back to its source, functioning like numerous small mirrors.

Fascinating Facts

Prismatic micro-reflective materials are designed so that light sequentially strikes each of the three surfaces that compose the micro prism before returning to its source. The trihedral micro prism structure is engraved on the lower surface of the transparent resin film using special moulds. The active layer is bonded to a substrate, the back of which is coated with an adhesive layer protected by a liner.

Visit our website to explore the complete range of High-Visibility Clothing