UNI EN ISO 11611

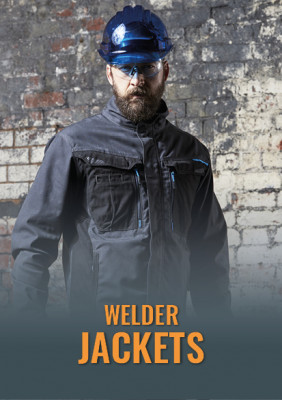

Welding Workwear

The UNI EN ISO 11611 standard specifies the fundamental safety requirements and testing methods for protective clothing designed to be worn during welding and related processes that pose similar risks. This standard covers hoods, aprons, sleeves (excluding gloves and hand protection PPE), and gaiters intended to safeguard the wearer’s body.

Welding Risks

The risk factors to which welding workers may be exposed are varied and can be categorised into two primary types: chemical risks and physical risks.

Chemical risks associated with welding operations stem from the generation of welding fumes. Welding fumes comprise a complex mixture of over 40 chemical, inorganic, and organic components released during the heating and eventual melting of the workpiece. Naturally, the composition and concentration of the chemical agents in welding fumes depend on the material being welded, the electrode’s composition, any filler materials, and substances covering the workpiece. The most substantial risk related to welding fumes is the presence of metals in a gaseous or particulate state to varying degrees.

Physical hazards arise from exposure to non-ionizing radiation, elevated temperatures, and noise. Both the flame and, to a greater extent, the electric arc emit optical radiation within both the visible and invisible spectrums. Ultraviolet radiation, the most energetic of non-ionizing radiations and therefore the most hazardous, is largely absorbed by the protective surface layers of the skin and can cause second-degree burns. Hence, protective clothing must cover the entire chest up to the wrists and the entire legs up to the ankles, providing protection against accidental contact with molten metal splashes.

Noise levels can be a result of typical oxyacetylene flame welding operations as well as from the electric arc, each with different impacts on hearing thresholds.

Apart from risks directly or indirectly linked to welding operations, there are those associated with the workplace environment and conditions (falling objects, limb crushing, limb entanglement in moving parts, working at heights, etc.), as well as the type of equipment used (electricity, gas cylinders, pipes, etc.). Ultimately, the microclimate, repetitive movements, and awkward postures must also be considered.

General requirements

Safety clothing for welders, following UNI EN ISO 11611, must possess specific characteristics, including:

- They must prevent the conduction of electricity from the outside to the inside.

- Pockets with exterior openings must be covered by a flap, with exceptions for side pockets sewn below the waist (with an inclination of no more than 10 degrees from the side seam) and side rule pockets (with a 75 mm opening, placed behind the side seam).

- Flaps should be at least 2 cm long, preventing them from being inserted inside the pockets. They must either be sewn down or capable of securely closing the pocket, covering various fastening systems.

- Cuffs can be adjustable but must not have turn-ups.

- If fasteners are used, they must allow complete closure with a locking slide fastener.

- Fasteners and folds that may form must be positioned on the back of the cuff.

- The neck opening must feature a fastening system.

- Trousers can have side openings with a covered fastening system, and the bottom must not have turn-ups. Fasteners and folds on the exterior of the garment must be on the garment’s interior.

More on the 11611 standard

Classifications

The UNI EN ISO 11611:2015 standard classifies clothing into two categories based on distinct features:

Class 1 |

Class 2 |

|---|---|

Type of process |

|

|

Low levels of molten metal splash and radiant heat

|

Higher levels of molten metal splash and radiant heat

|

Type of work |

|

|

Machinery

|

Machinery

|

Exposure to splash impactsA temperature increase of 40K |

|

| 15 drops | 25 droops |

Radiant heat transferWith a heat flux density of 20Kw/m2, the radiant heat transfer index (RHTI) for 24° C (RHTI 24) |

|

| RHTI 24 ≥ 7s | RHTI 24 ≥ 16s |

Test methods

The UNI EN ISO 11611 standard defines two test methods to evaluate the garment’s flammability.

- A1: This marking signifies that the garment passed the surface ignition test, remaining intact.

- A2: When the garment passes the lower edge ignition test, it bears this symbol.

- A1+A2: In this case, the garment successfully passed both tests.

Learn more about the features of other certified safety garments designed for accident prevention, including

Visit our website to explore our complete range of Welding Protective Workwear